Slow RCSB bagged build

- Thread starter FTC

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

this nigga speaks truthHaha yeah got it just for this build. Gets all the crap off the ground if I need to lie down, and make clean up easy just shoot everything next door haha.

Sent from my SAMSUNG-SGH-I747 using Tapatalk

Ok no more tapatalk uploads, photobucket comes out much nicer just couple more steps.

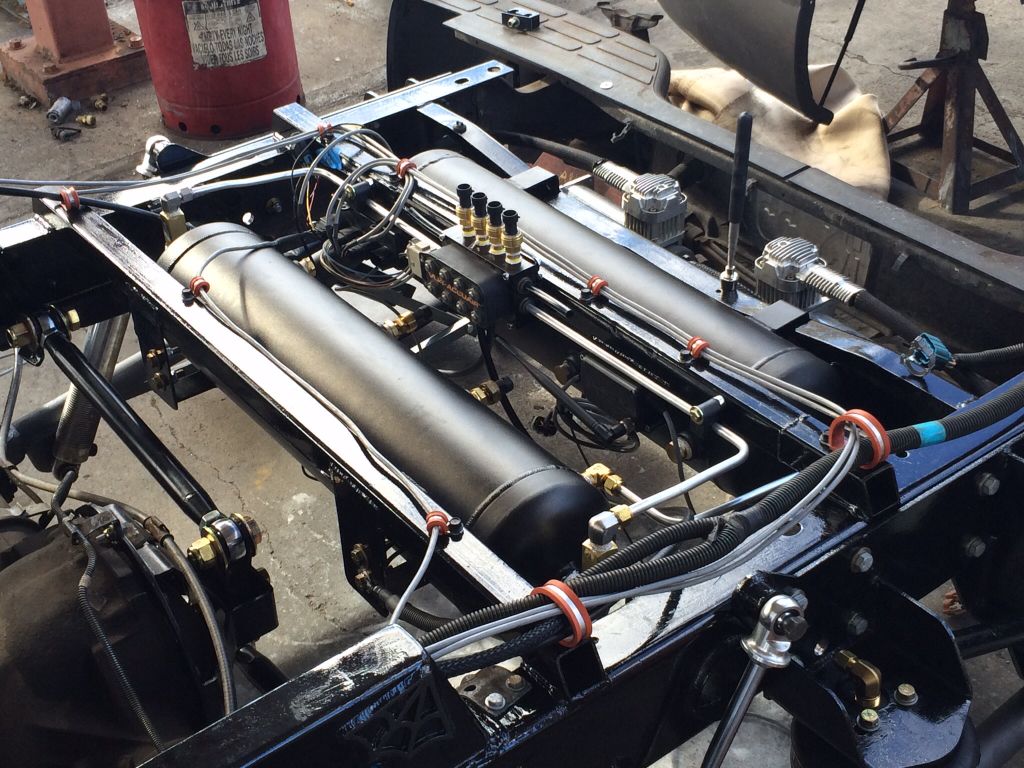

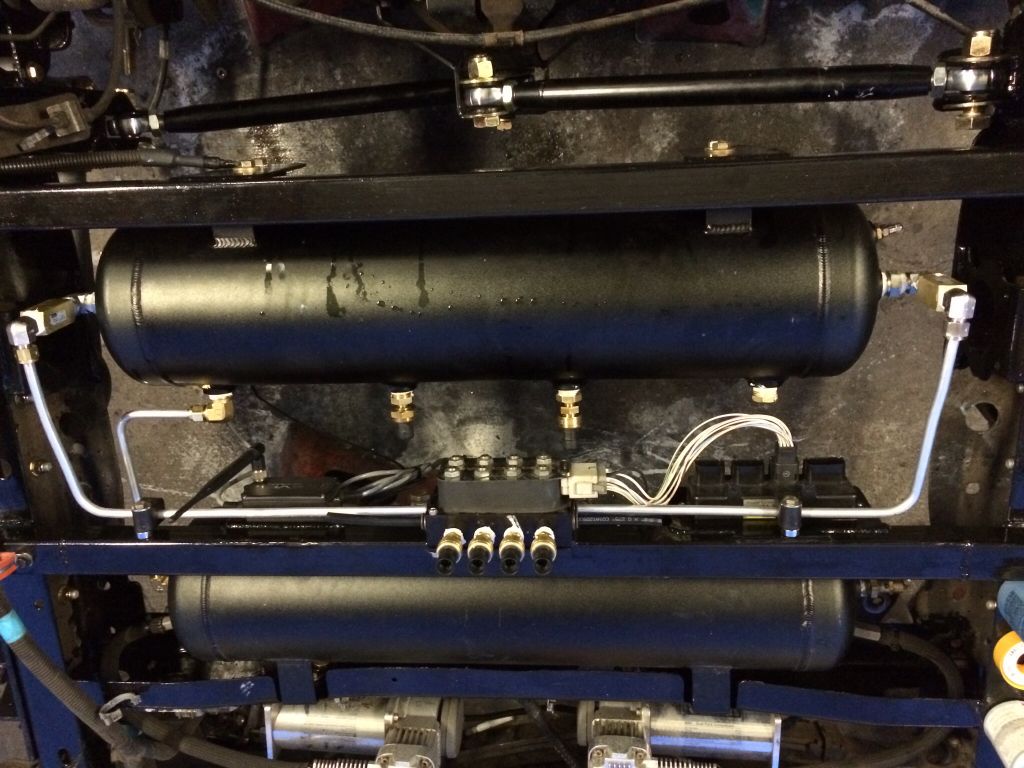

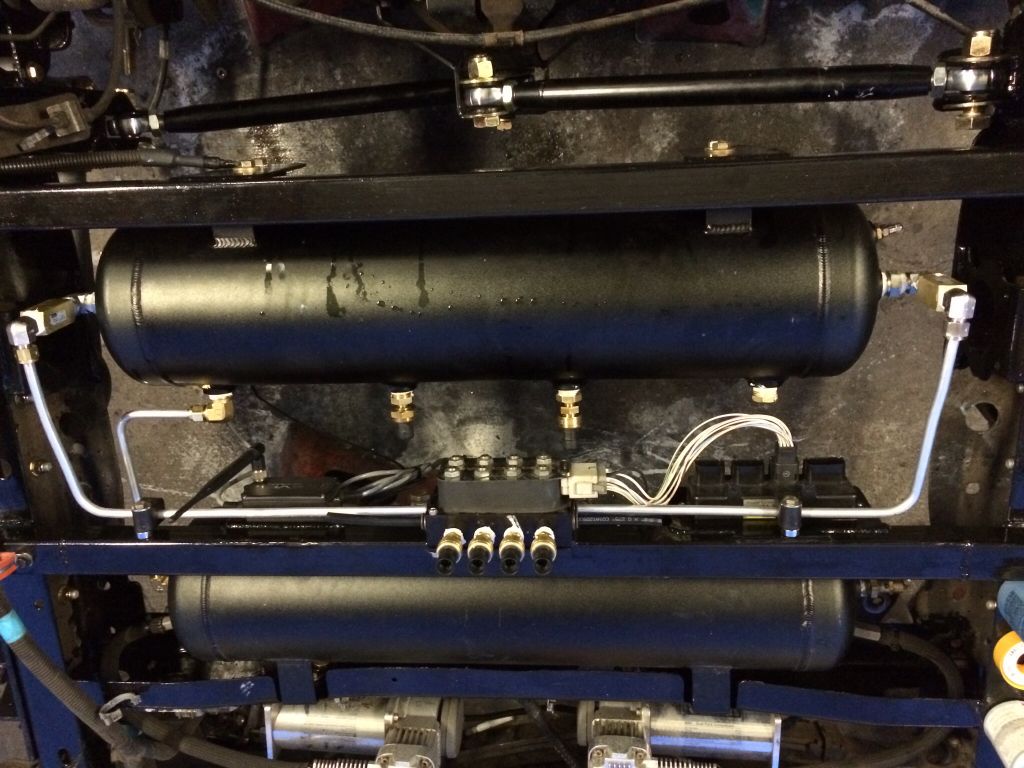

Tank crossmembers are raised, air management redo is mocked up. Almost to the point I can start putting stuff together. Gonna cycle the suspension with the bed off before I reassemble.

Crossmembers raised 1" front and 1.5" rear.

Air management redo

Also keeping with the webbed theme, probably will never be seen but I needed a gusset and these were handy.

Welds on step notch

Tank crossmembers are raised, air management redo is mocked up. Almost to the point I can start putting stuff together. Gonna cycle the suspension with the bed off before I reassemble.

Crossmembers raised 1" front and 1.5" rear.

Air management redo

Also keeping with the webbed theme, probably will never be seen but I needed a gusset and these were handy.

Welds on step notch

Last edited:

Thanks Jared! Trying to keep everything updated as I go so I don't forget. Or I hate when there's a build and the part you were wondering about is done with no pic of it. So I try to take pics at the end of each day.

Not a whole lot done today, got the air management all welded in and setup, just need to run the lines. And installed the 6 link to set pinion angle, wheelbase and tack in the watts brackets. I found a place to powder coat the 6 link for 180 which seems to be a decent price. So after mock up I will break it all down, send it out and work on painting the frame in the meantime. Finally she got up under her own power. Lift seems insane with no shocks and no weight on it. The frame came out pretty rigid, when I lift a corner by hand the other end immediately moves too, so I figure there is very little flex in it.

Lifted to 70 psi

Dumped

Not a whole lot done today, got the air management all welded in and setup, just need to run the lines. And installed the 6 link to set pinion angle, wheelbase and tack in the watts brackets. I found a place to powder coat the 6 link for 180 which seems to be a decent price. So after mock up I will break it all down, send it out and work on painting the frame in the meantime. Finally she got up under her own power. Lift seems insane with no shocks and no weight on it. The frame came out pretty rigid, when I lift a corner by hand the other end immediately moves too, so I figure there is very little flex in it.

Lifted to 70 psi

Dumped

Got mostly everything painted up, used por 15. It's too much work to take all that undercoating off so I left the inner channel untreated. On to reassembly, hoping to be able to get the bed back on sometime this week.

Went with por manifold paint to get some contrast to the webs, but I don't like how it came out and will prob switch to regular paint. The manifold paint is so thick it's hard to get a clean line. Will probably go with some duplicolor touchup paint and color match to the exterior color. I was even thinking just grind off the por and clear over bare metal.

Frame brackets

Crossmembers

Went with por manifold paint to get some contrast to the webs, but I don't like how it came out and will prob switch to regular paint. The manifold paint is so thick it's hard to get a clean line. Will probably go with some duplicolor touchup paint and color match to the exterior color. I was even thinking just grind off the por and clear over bare metal.

Frame brackets

Crossmembers

Only got to work on it for a couple hours today. Put in the gas tank to check fitment, everything seems fine. Ended up breaking one of those vacuum tees for the vent lines on the tank so will have to patch that up. And my dumbass didn't install the forward 4 link bracket, so tank will have to be dropped again to get to the backside easier. Also started some of the line routing, I won't be using zipties as much as possible, I'm gonna try and hard mount everything. Nutserts so make this super easy.

Thanks mike! Trying my best while I have the time to do it, takes way longer to do it the way I want it vs just so it works.

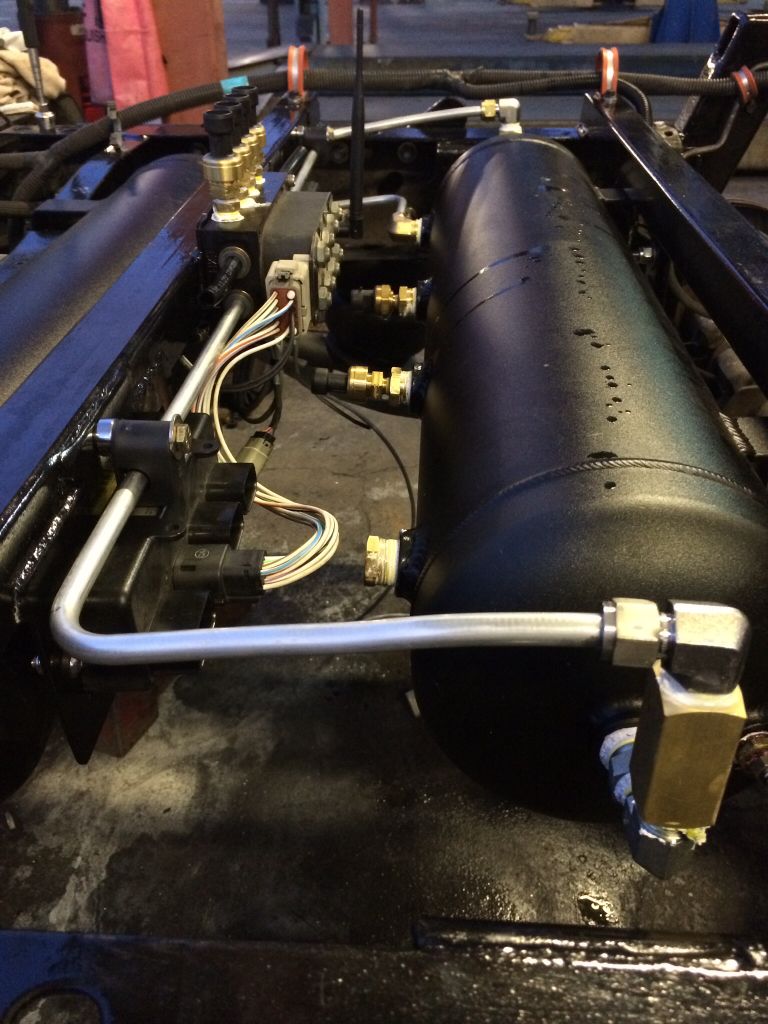

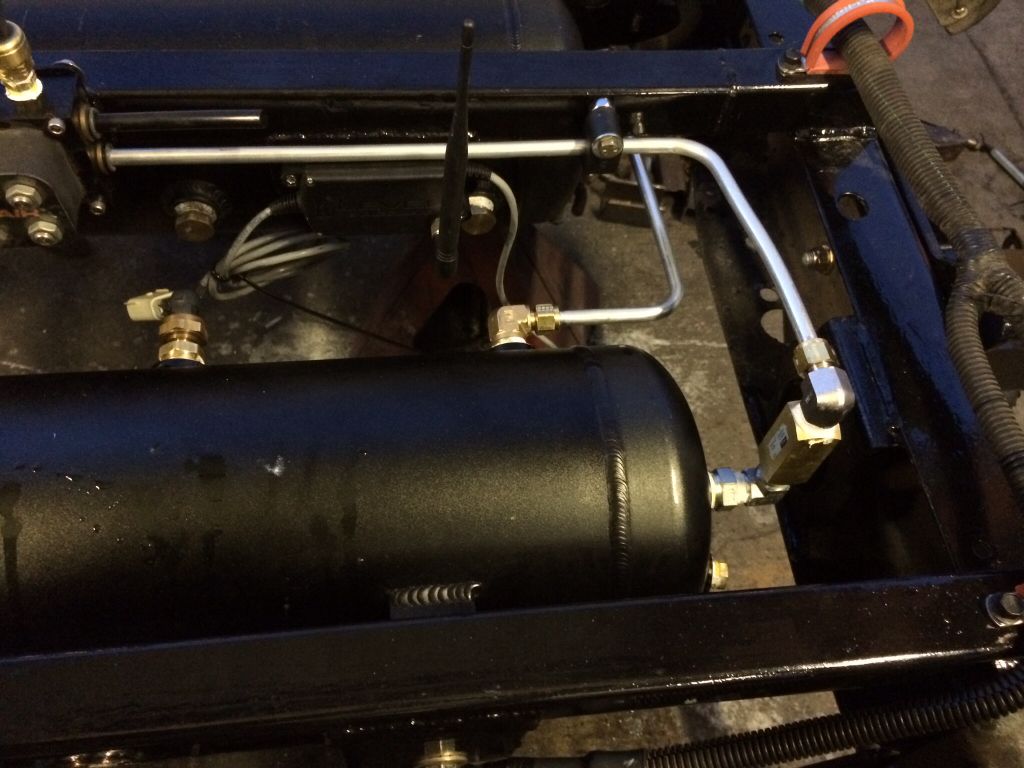

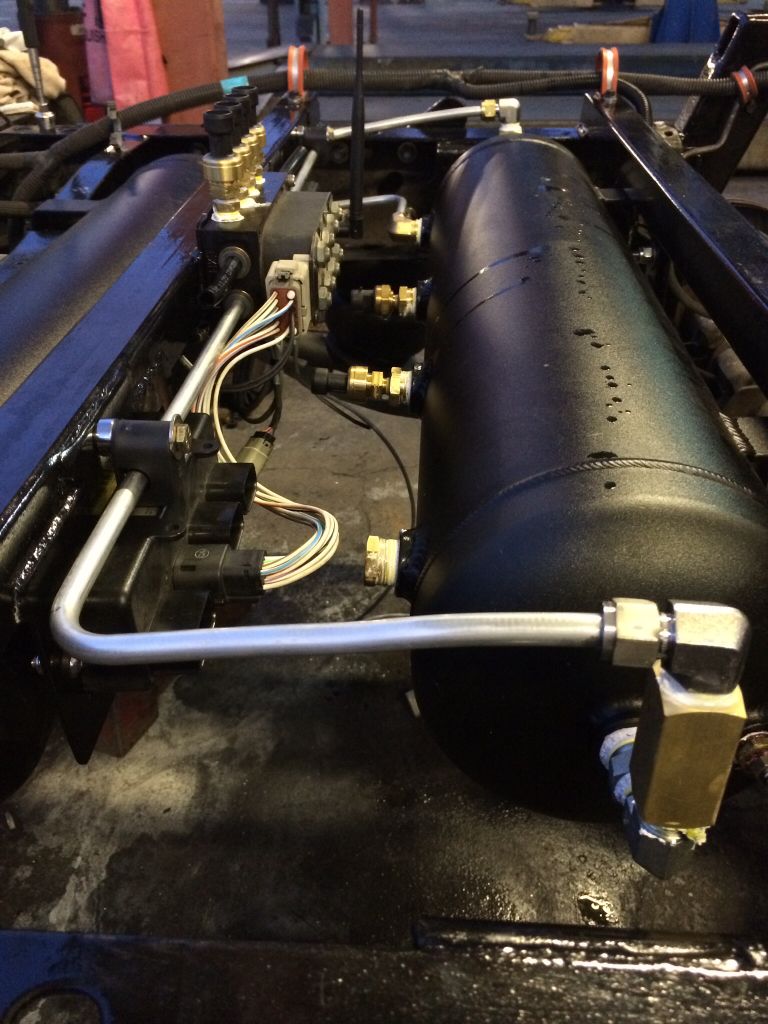

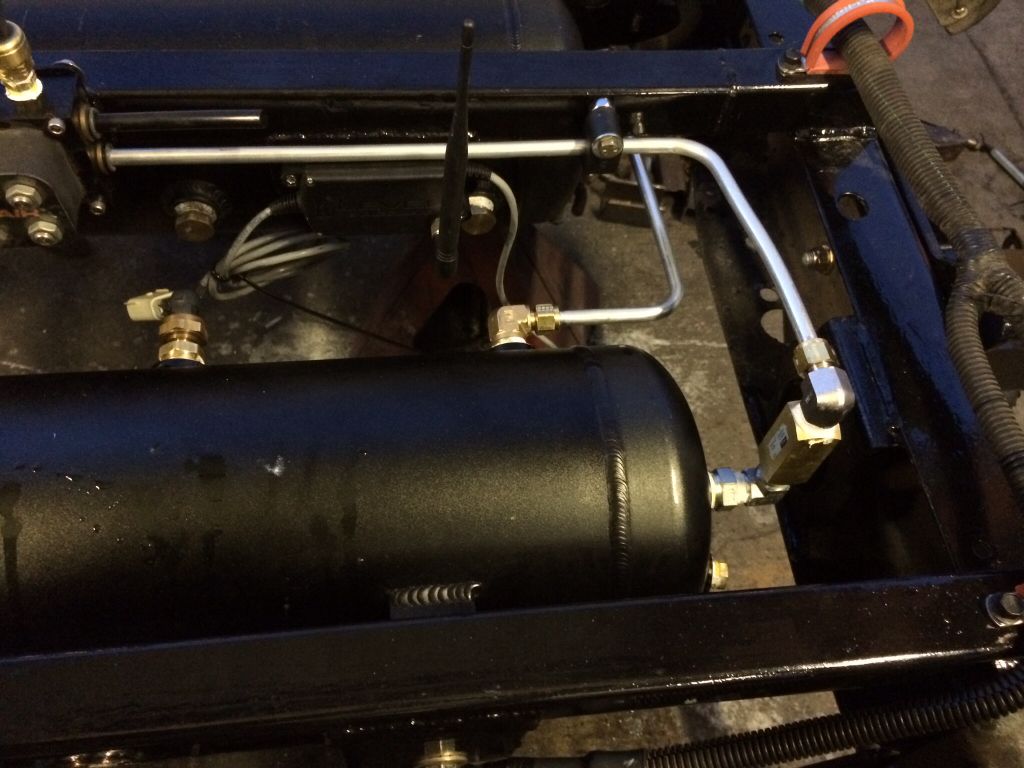

Got most of the air management plumbed up today, tried my hand at some hard lining. Came out pretty good I think, used aluminum tubing. Real easy to work with, and no leaks from MY connections. As with the rest of my luck with this build, the additional tank I added has a pin hole leak in one of the bungs... Bad weld. Not sure what I'm gonna do yet but prob contact avs for a new one, in the meantime I'm just gonna try and jb weld it temporarily, if it was steel I would just weld it up, but being its alum I think it's easier to just replace it. Tomorrow, gonna run the wiring and hopefully get to adjusting the 4 link and watts. And dumb ass specialty suspension fucks me again, the rod ends are all right hand thread on the watts so, the ends have to be taken out of the mounts to lengthen/shorten them, a real pain in the ass.

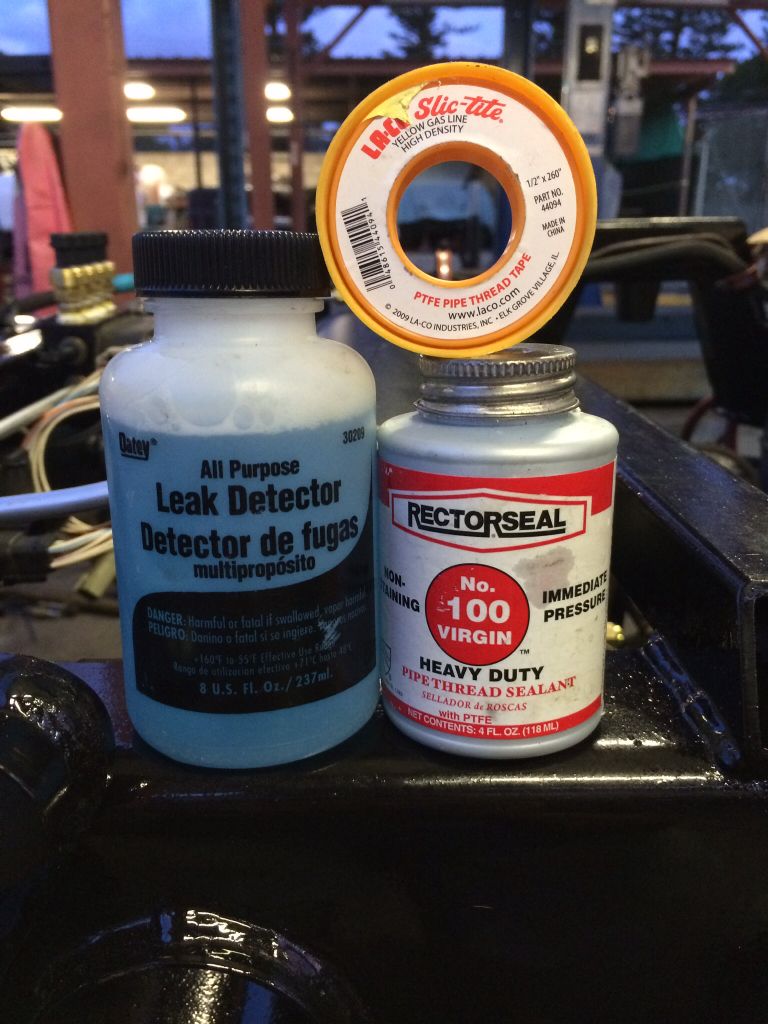

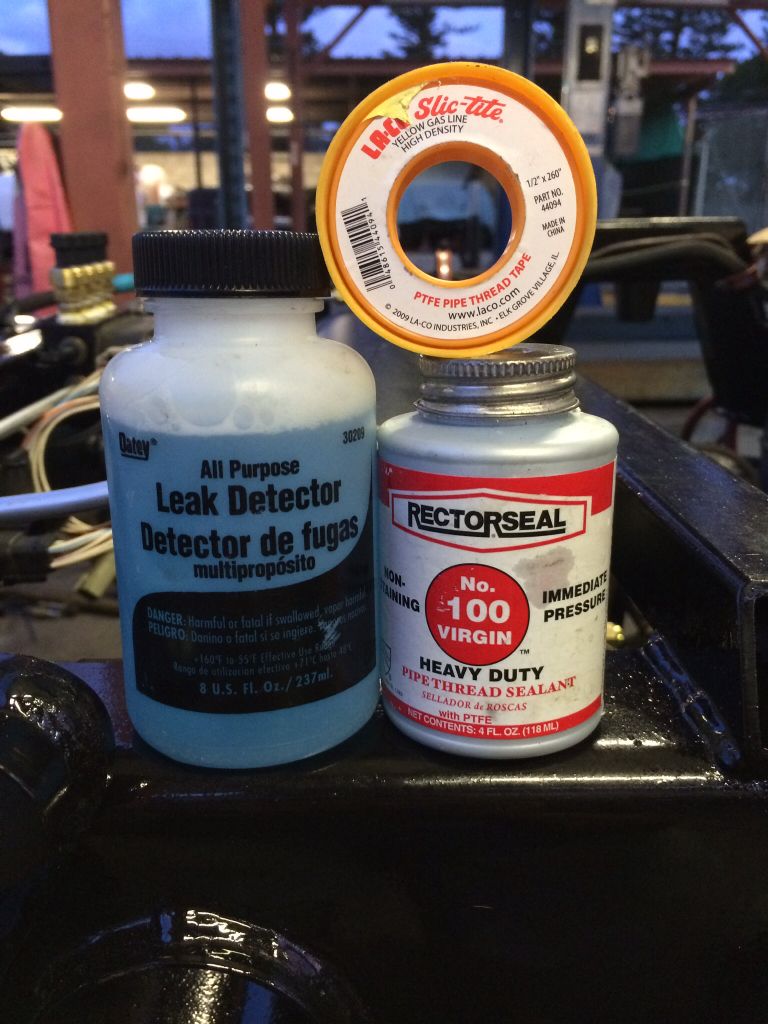

Weapons of choice, I also use loctite 545 for small fittings 1/4" and smaller cause the rectorseal is just too hard to apply to that small area.

Hardlines

Leak at the WELD not the plug

Painted 6 link installed, grey came out pretty nice I think, definitely a different color but not a huge contrast. Which is what I'm going for, something's done but still subtle.

Got most of the air management plumbed up today, tried my hand at some hard lining. Came out pretty good I think, used aluminum tubing. Real easy to work with, and no leaks from MY connections. As with the rest of my luck with this build, the additional tank I added has a pin hole leak in one of the bungs... Bad weld. Not sure what I'm gonna do yet but prob contact avs for a new one, in the meantime I'm just gonna try and jb weld it temporarily, if it was steel I would just weld it up, but being its alum I think it's easier to just replace it. Tomorrow, gonna run the wiring and hopefully get to adjusting the 4 link and watts. And dumb ass specialty suspension fucks me again, the rod ends are all right hand thread on the watts so, the ends have to be taken out of the mounts to lengthen/shorten them, a real pain in the ass.

Weapons of choice, I also use loctite 545 for small fittings 1/4" and smaller cause the rectorseal is just too hard to apply to that small area.

Hardlines

Leak at the WELD not the plug

Painted 6 link installed, grey came out pretty nice I think, definitely a different color but not a huge contrast. Which is what I'm going for, something's done but still subtle.

Trust me when I say you'd rather get a new one then weld right on the tank

Sent from a secure terminal using the classified military network

Sent from a secure terminal using the classified military network

Why is that? I weld on pressure vessels for a living, probably one of the biggest pressure vessels there is....nuclear fast attack subs. It's just that I don't have access to an ac tig machine.

So I'd assume u don't have acces to x-Ray or ultrasound to check the welds either? Never said I doubt your welding ability

Sent from a secure terminal using the classified military network

Probably could do a pt(penetrant test) which I would think is sufficient, and probably find way more stuff wrong then I'd like to know. But like you said it's easier just to get a new tank. I just don't want to disassemble it, rather weld it in place, cause hardlines are all routed and fittings don't leak, etc, etc.

So I'd assume u don't have acces to x-Ray or ultrasound to check the welds either? Never said I doubt your welding ability

Sent from a secure terminal using the classified military network

I was planning on just bubble testing it again, plus I highly doubt these tanks are ut or rt inspected prior to sale anyway. If they were I wouldn't have this problem in the first place. and none of them would pass inspection, aluminum is super hard to pass xray.