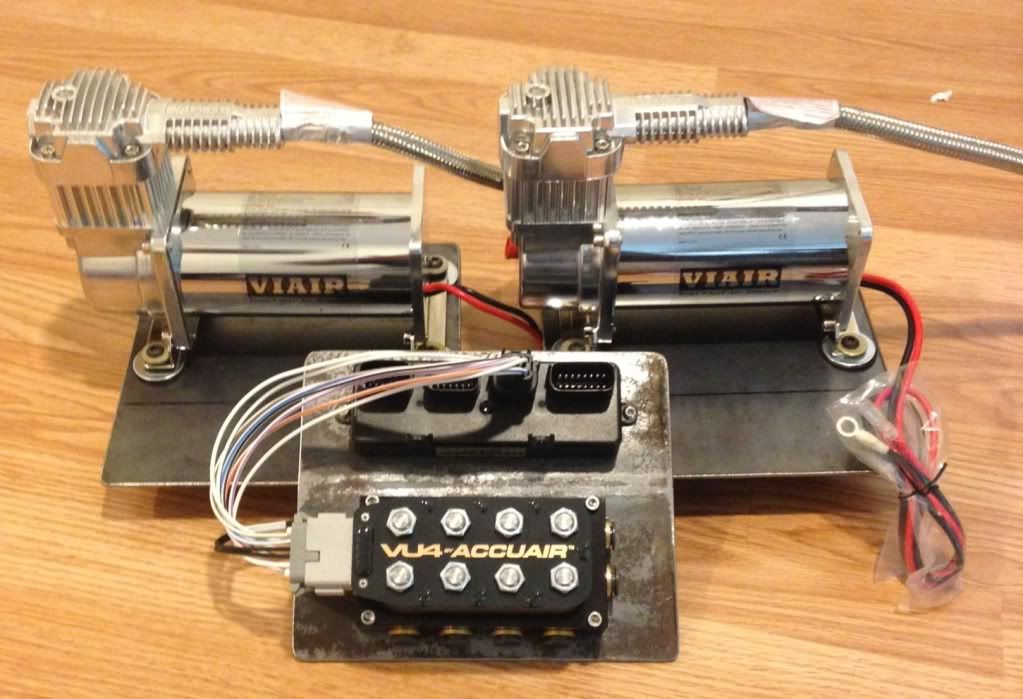

Finally some progress on the truck!!! Not a whole lot but its a start, still need to route all the lines and stuff. I want the air management to be up and running before I start on the suspension stuff. On to the pics.

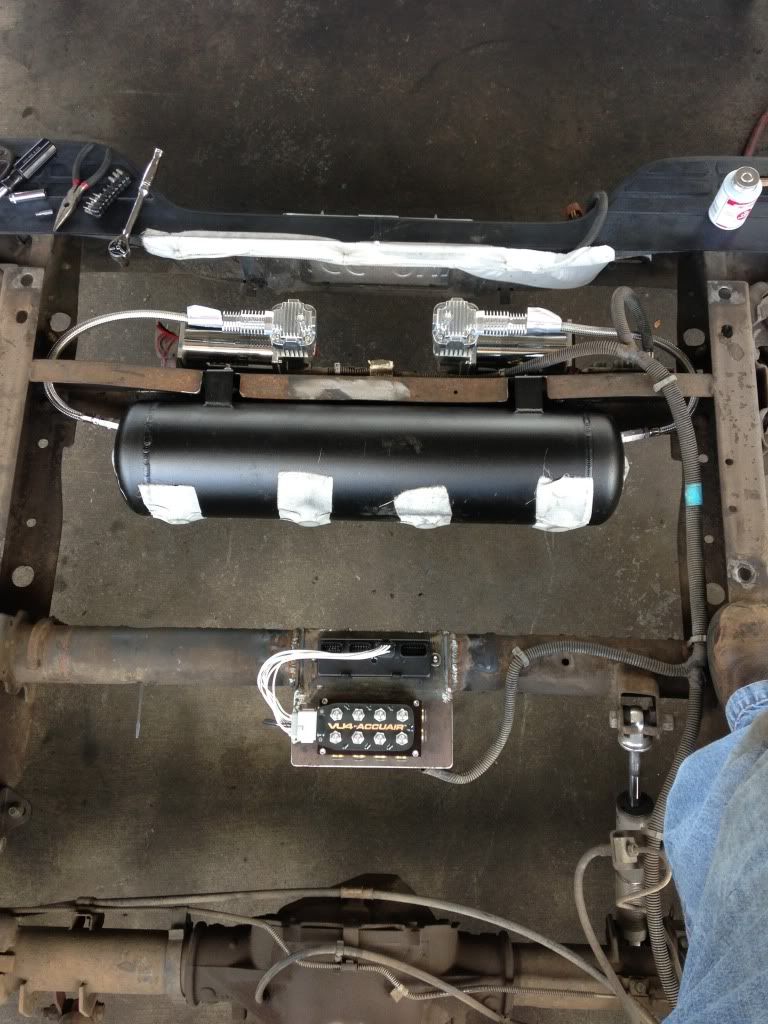

This is how I ended up mounting everything, my goal was to keep everything tucked up as high as possible, don't like the look of tanks etc hanging down. I was able to keep everything above the lowest part of the bumper.

Vu4 and ecu mounted to the tube crossmember, I tried to use what I had available. I think eventually I will cut this out and fab up another. Later I'm probably going to be adding another 5 gal and there's not enough room with that crossmember there. I just cut down half way into the tube and plated it, plenty of room to the bottom of the bed.

Another shot of the valve mounting, I ended up tacking the nuts to the backside of the ecu part cause they couldn't be accessed, and I didn't feel like drilling holes on the underneath. Side note, this was my first time really using a mig welder, it welds pretty decent. Definitely easier and faster to use than stick or tig. I'm still a little confused with the settings so I just messed with them till it welded decent.

Compressor mounting, can't see real good in this pic but they are dropped down a little with box tube standoffs. Otherwise they would have hit the bed floor pinch weld.

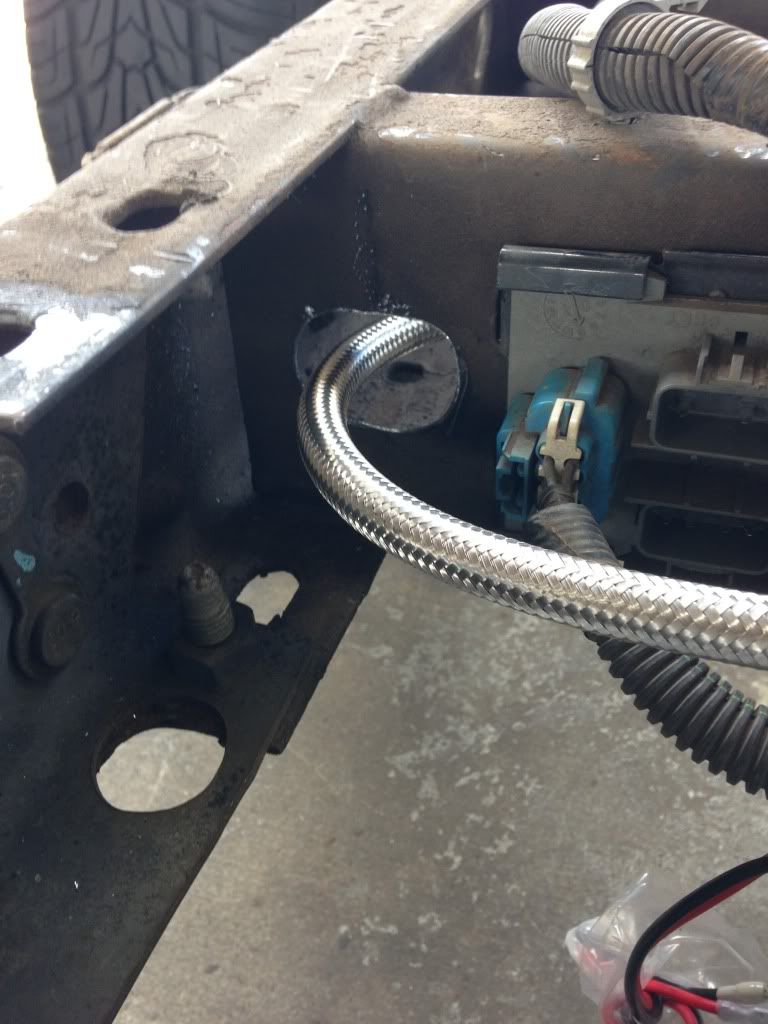

Punched some holes in the crossmember for the leader hoses to pass through, I originally wanted to run water traps on the compressors but the way I mounted the tank wouldn't have enough space. So I think ill just run 1 off the tank to the vu4 block. I'm not too concerned about rust inside the tank as its aluminum and I do have a drain on the bottom port.

That's it for now, ill probably be running lines next so it might be a while before I get to the suspension.