the 3k extra you have from selling the old truck gonna go into a lowering kit, wheels and tires?

DA new Truck

- Thread starter DemoN

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

thats a hell of an opportunity posted. Tough to give up a warranty so early on in ownership though.

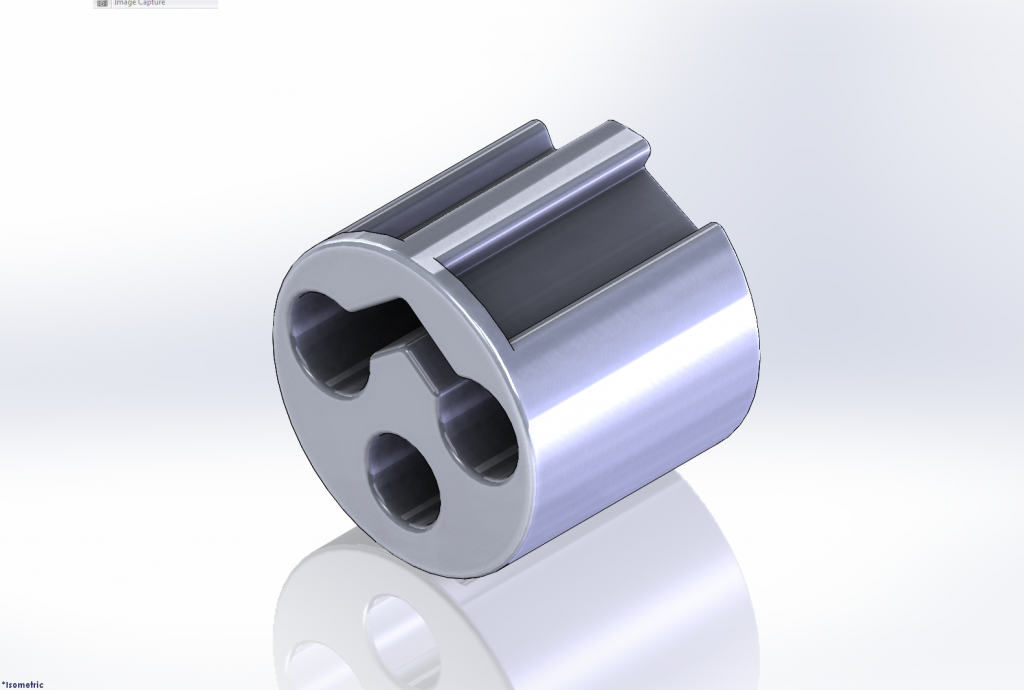

made of a plastic or rubber?

ABS plastic. i'll probably sand and paint it in the future.

thats pretty cool looking. one thing i wish i was good ad was being able to whip something up quick in solid works. that looks simple, but you can get very carried away with detail on something like that. had a professor make shit all the time in a 3D printer.

thats pretty cool looking. one thing i wish i was good ad was being able to whip something up quick in solid works. that looks simple, but you can get very carried away with detail on something like that. had a professor make shit all the time in a 3D printer.

i wanted something simple, looked good, and had bottom end weight.

i could get complicated with my models if i wanted lol

i cant look at that without cringing, makes me feel like im back in school lol. i remember i spend a week on my final project in solid works on bike forks because i didnt have the proper dimensions, then realized i only had 2 days to do the rest of the bike. needless to say the rest of it when put together looked like some ghetto shit lol. you can get very carried away with stuff and you dont even realize it until you have been in front of the computer for like 16 hours lol.

what do you do anyways (job wise)

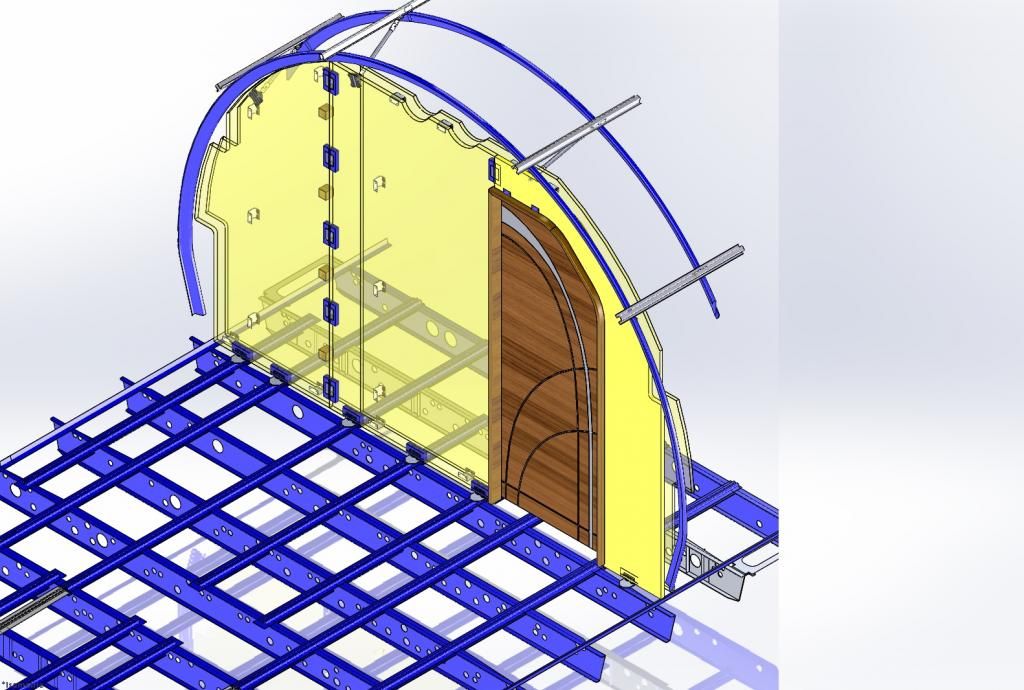

i recreated the kp 6 link in solidworks for my final project

i cant look at that without cringing, makes me feel like im back in school lol. i remember i spend a week on my final project in solid works on bike forks because i didnt have the proper dimensions, then realized i only had 2 days to do the rest of the bike. needless to say the rest of it when put together looked like some ghetto shit lol. you can get very carried away with stuff and you dont even realize it until you have been in front of the computer for like 16 hours lol.

i recreated the kp 6 link in solidworks for my final project

I really need to learn solid works. I used to use autodesk inventor, but they use solid works here at the shop.

Sent from my SAMSUNG-SGH-I337 using Tapatalk

Sent from my SAMSUNG-SGH-I337 using Tapatalk

i recreated the kp 6 link in solidworks for my final project

nice. i gotta say i think my class was like once or maybe twice a week, you cant learn in depth solid works like that in 10 weeks IMO. everyone had used it before and autocad, my highschool didnt do anymore more than a keyboard class lol.

solid works is ok, i used autocad inventor in high school, recreated complete front suspension with travel as my final project.

i used solid works at college as well as regular autocad.

at work, all i use is autocad.

i used solid works at college as well as regular autocad.

at work, all i use is autocad.

Inventor seems more user friendly to me than solid works. The only reason I need to learn more on solid works is so I can pull up prints/models when I need more information on a part thay the engineers didnt give me. We have a computer in the tool room that we can pull parts up on if we need to. Our engineers arent worth a shit so we constantly have to go back and add dimensions and shit. Been getting worse here recently too.

Sent from my SAMSUNG-SGH-I337 using Tapatalk

Sent from my SAMSUNG-SGH-I337 using Tapatalk

demon i forgot to ask, is there limits of what you can print material wise? i imagine it cant print like aluminum or anything right?

has to be plastic based?

has to be plastic based?

demon i forgot to ask, is there limits of what you can print material wise? i imagine it cant print like aluminum or anything right?

has to be plastic based?

there's a few materials we can use, but there are plastic based. ABS is a common, nonstructural, plastic. we also use higher grade material that has almost triple the shear strength (but still a 1/5 of 2024-t3 aluminum @ .063thk).

we're currently experimenting on "skeletons" for parts with more structural requirements. building an aluminum rib cage and printing around it.

interesting. would be sweet to have one to make the rollers we use at work, but they are all UHMW

nothing got done to the truck it's self yet.

i spent some time sunday working on the garage. the reverse safety sensors were burned and the garage door opener remote didn't work. so i replaced both of those.

i discovered that my garage, with the work bench that was built in, was just a TAD too short to fit the truck. so i ripped out the bench and rearranged the entire garage so the truck fits well. by noon, i got it to fit lol

i spent some time sunday working on the garage. the reverse safety sensors were burned and the garage door opener remote didn't work. so i replaced both of those.

i discovered that my garage, with the work bench that was built in, was just a TAD too short to fit the truck. so i ripped out the bench and rearranged the entire garage so the truck fits well. by noon, i got it to fit lol