Well tried a local truck pull last Saturday, and I'll let the video explain what happened...

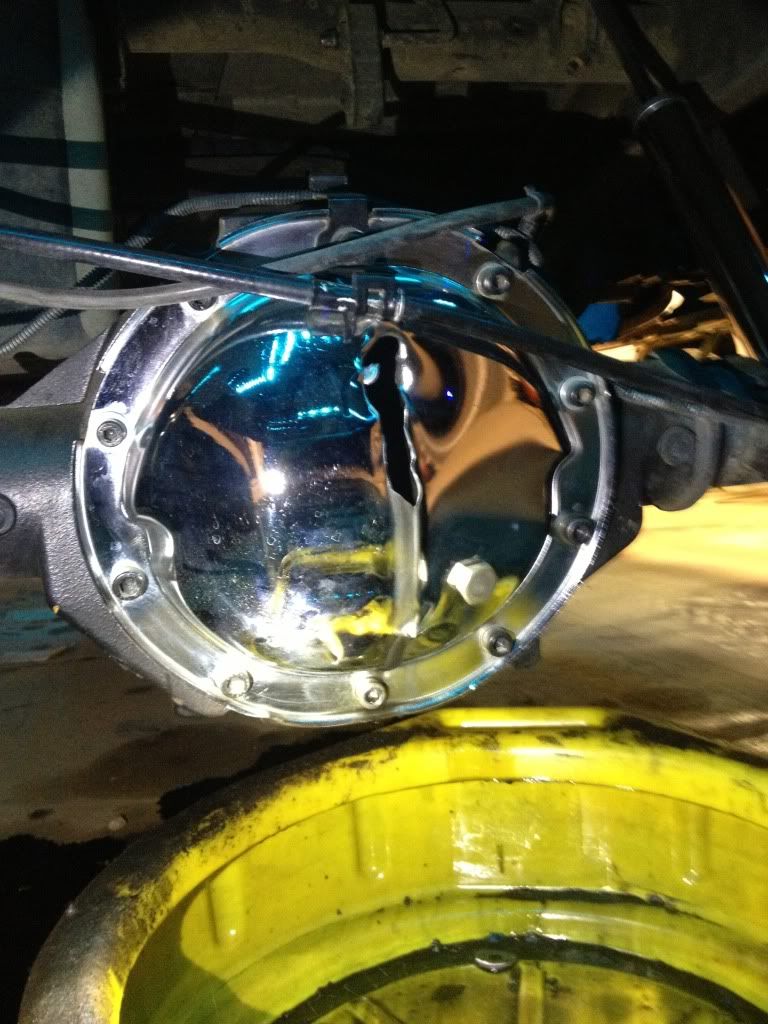

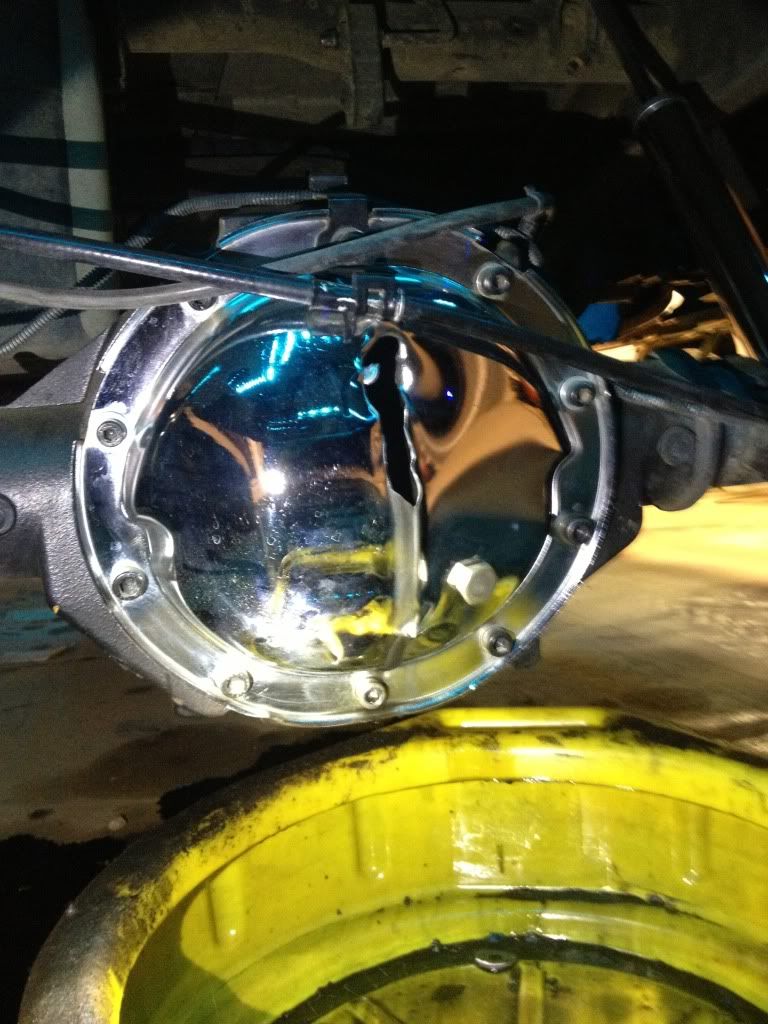

Well that ended in this.

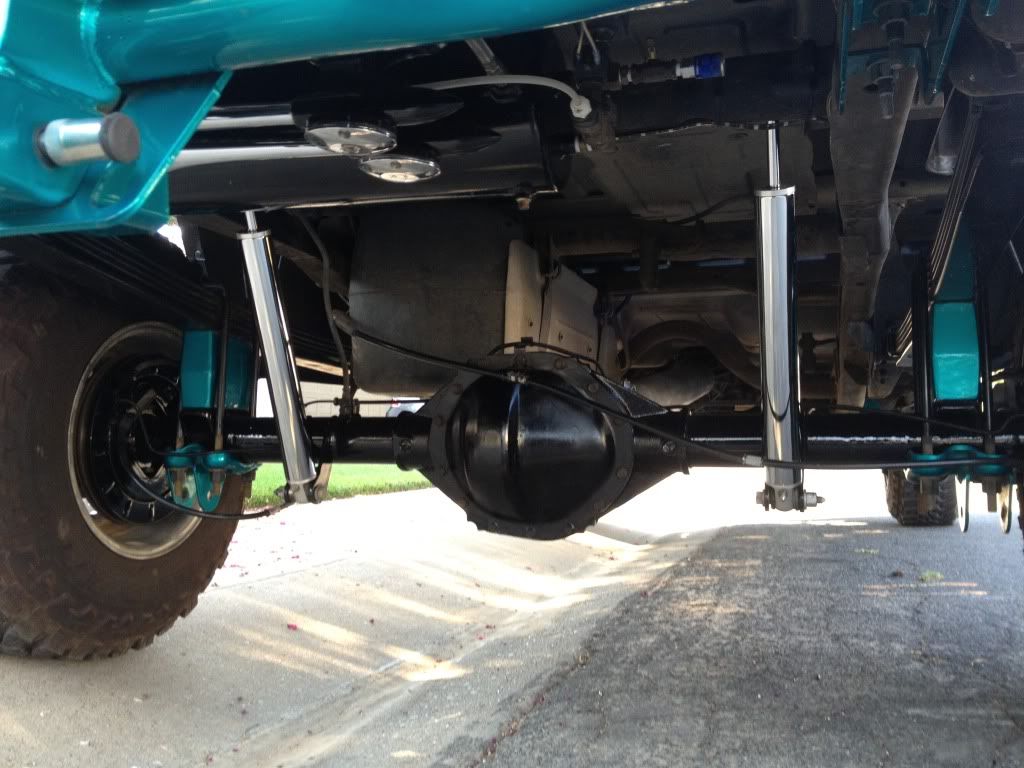

We towed it home in style on a good friend's lowboy

So that brings us to yesterday, when I finally pulled the rearend apart

Good news is it's time for an upgrade, so I got a 9.5" 14 bolt from a obs 2500 6 lug and am going to have to move the spring perches, shocks tabs, and caliper mounts to use my disc brakes and have shocks both on the rear of the axle.

Also doing a full rebuild of the axle, all new bearings and seals, and installing a Detroit locker.

Well that ended in this.

We towed it home in style on a good friend's lowboy

So that brings us to yesterday, when I finally pulled the rearend apart

Good news is it's time for an upgrade, so I got a 9.5" 14 bolt from a obs 2500 6 lug and am going to have to move the spring perches, shocks tabs, and caliper mounts to use my disc brakes and have shocks both on the rear of the axle.

Also doing a full rebuild of the axle, all new bearings and seals, and installing a Detroit locker.

Last edited: